Checkerboard Weave! This is my favorite weave. It is a simple weave that helps build skill and control with the wire. It can be used may ways in design and handles curves well, since there are spaces between the wrapped sections.

* Step 1: Select wires of two different gauges. One heavier gauge wire, which will be for your two base wires, and a thinner gauge wire to do the weave with. Here, I have used 21 gauge square copper wire for the two base wires, and 24 gauge black enameled copper wire to weave with.

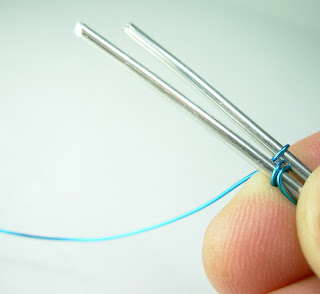

* Step 1: Select wires of two different gauges. One heavier gauge wire, which will be for your two base wires, and a thinner gauge wire to do the weave with. Here, I have used 21 gauge square copper wire for the two base wires, and 24 gauge black enameled copper wire to weave with.  * Step 2: Begin by wrapping your the wire you are weaving with around the base wire four times. You will notice I started with the left base wire and wrapped the weave wire in a clockwise fashion. Sometimes it is easiest to set aside the second wire while you do this very first wrap. Then when your are ready to start the first wrap on the second wire, you can add that wire between your fingers. As I mentioned in the previous post, you may choose to hold the wires together with a little piece of painter's tape here at the beginning to stabilize the wires so they don't move around in your hand.

* Step 2: Begin by wrapping your the wire you are weaving with around the base wire four times. You will notice I started with the left base wire and wrapped the weave wire in a clockwise fashion. Sometimes it is easiest to set aside the second wire while you do this very first wrap. Then when your are ready to start the first wrap on the second wire, you can add that wire between your fingers. As I mentioned in the previous post, you may choose to hold the wires together with a little piece of painter's tape here at the beginning to stabilize the wires so they don't move around in your hand.*Step 3: You are ready to add the second base wire. Run your weave wire through the middle, and the back around the outside.

* Step 4: Every fourth wrap will be like a figure 8 between the wires. You will do three complete wraps on each side, and on the fourth wrap, you will cross to the other side. As you are doing this, make sure each time you cross to the other wire, that the distance between the wires remains parallel. Sometimes it is necessary to run the unwoven portion of your base wires through a pair of soft jaw pliers to straighten them again. If your groupings if four don't seem quite even, gently squeeze them together using your half round pliers (or your fingernails, if you are lucky enough to have them).

* Step 4: Every fourth wrap will be like a figure 8 between the wires. You will do three complete wraps on each side, and on the fourth wrap, you will cross to the other side. As you are doing this, make sure each time you cross to the other wire, that the distance between the wires remains parallel. Sometimes it is necessary to run the unwoven portion of your base wires through a pair of soft jaw pliers to straighten them again. If your groupings if four don't seem quite even, gently squeeze them together using your half round pliers (or your fingernails, if you are lucky enough to have them). *Step 5: Weave to your heart's content. There are many variations that can be done with this weave. Beads can be added in the open spaces as you go. Or, you may choose to do a different amount of wraps on each of the base wires. Just play and have fun!

*Step 5: Weave to your heart's content. There are many variations that can be done with this weave. Beads can be added in the open spaces as you go. Or, you may choose to do a different amount of wraps on each of the base wires. Just play and have fun! If you have any questions about this weave, please feel free to ask. And let me know if I need to be more clear in my explanations. Thanks!